OSR equipment supplied for self-propelled bunkering tanker project RT-37

29.01.2019

This newest eco-class vessel will be operated in Baikal. The tanker is designed for loading of oily and waste waters from small boats, which will allow to drastically reduce the volume of oil-containing products contaminating the lake.

The vessel is currently under construction on the building berths of the East Siberian Inland Navigation Company. Designed by the Marine Engineering Bureau on the basis of already built ships RT-18 and RT-29, this vessel has got the highest river class - M, provided the draught of 1.80 m.

The main function of the vessel is to load from shore, transport, and to unload on shore or to another ship different oil products, diesel fuel, and lubricating oils with viscosity of up to 50 cSt. But the vessel, named by its designing team as a "tanker-plant", not only loads the wastes, but also performs the treatment.

However, the vessel is capable not only of loading wastes in regular situations, but also acts as an additional instrument for oil-spill response, because it's equipped with oil products skimmer that works on the water surface.

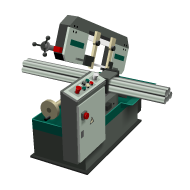

Oil skimmer DBD 16 by DESMI RO-CLEAN, supplied to the vessel by Kronstadt Engineering Company, provides fast and timely absorption of oil, oil products, or specific oils from water surface in the operation zone. Using of skimmers make cleaning works a lot easier, especially in ports that operate with oil and combustible mixtures.

Disk mop skimmer DESMI DBD 16 – is a mid-sized skimmer with two rotating disk modules or two mop drums, depending on the application. Both element types can be interchanged quickly, which gives the device its versatility in different conditions. When the disks or drums rotate on the surface, oil products stick to them, and then they are skimmed and sent to the central collecting tray of the skimmer head, creating constant flow to be discharged.

This skimmer module is highly efficient with the rate of up to 99%!

The skimmer working speed can be adjusted for optimizing its collecting efficiency and achieving of max performance at 15 m3 per hour.